Corporation Home | Site language:Chinese | English

| About | Idea | Corporate Culture | Company News |

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

Pu’er Jiangcheng Fuwang Coffee BiotechnologyCo.,Ltd is in Pu’er city which is widely known as the Hometown of Chinese Coffee. The coffee base is locat...

Global sales department address: Room 9floor, Beijing Building, A6 Garden, Financial & Trading Zone, Haikou, Hainan, P.R.China 570125

Tel:(86-898)66729565 36667880

Fax: (86-898)66729560

E-mail: coffee@sinofuwang.com

Website: www.greencoffeebean.cn

Tel:(86-898)66729565 36667880

Fax: (86-898)66729560

E-mail: coffee@sinofuwang.com

Website: www.greencoffeebean.cn

企业注册信息公示扫码

Quality Control

We have carried out strict checks on processing procedures including planting, harvesting, collecting, washing inventory and other processing procedures in order to provide customers with high-quality coffee beans. Also we will strictly check the quality of our coffee products before shipmentat, at the same time we will send sample to the third-party quality inspection agency for test. Quality control procedure is as follows:

1. Checking soil and water of Coffee plantation

In the earlier stage of construction of coffee base we will test and evaluate the soilwater and surrounding environment. And then we will conduct periodic testing each year to ensure that the environment could adapt to the growth of the coffee.

2. During the cultivation process of Coffee tree prohibited chemical fertilizers and pesticides and prolific use of farmyard manure and ecological organic fertilizer are to prohibited; in insecticidal disease prevention natural enemies of pests natural plant extracts insect net insecticidal lamps pest prevention are used so that we can reduce the residues of harmful substances and to enhance the quality of the coffee beans.

3. In the coffee harvest season we only pick those ripe red berries and higher quality coffee beans with 8-10 day intervals by hand. Those coffee fruit with similar sizematurity and without other impurities are favorable for processing.

4. Before processing of the coffee fruit we will pick out coffee fruit which is not fresh or rotten; Through water floating again screen out unqualified coffee fruit and properly handle them.

5. Ensure adequate water in the process of peeling and washing. 50 gallons of water is need for per 1.5 cubic feet of coffee fruit; all equipments should be kept clean to prevent pollution of the coffee fruit. Washing waste disposal equipment also should be put in the right position to ensure that: the solid waste could be separated from the water ,and the sewage could be cleaned.

6. We have professional site and personnel which to dry the coffee beans to ensure the max moisture is 12.5%,while we select each grade of coffee beans by strict grading process,and separately stock them.

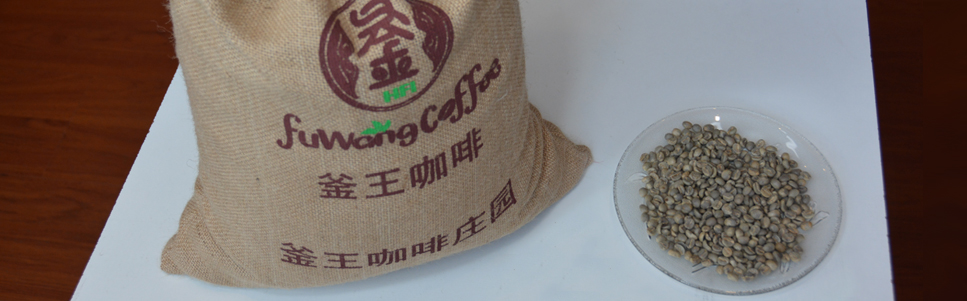

7. Packaging and storage We take methods such as shading ventilation to cooland prevent microbes breeding if not it will damage products. We select standard packaging materials with normative size which does not destroy the original state.

About | Contact | About | Job | Official microblogging

Copyright 2012 PU'ER JIANCHENG FUWANG COFFEE BIOTECHNOLOGY CO.,LTD All Rights Reserved. ICP:琼ICP8565243号

Address:Hainan Haikou, Guomao Road, Beijing Building Tel:(86-898)66729565 36667880

Copyright 2012 PU'ER JIANCHENG FUWANG COFFEE BIOTECHNOLOGY CO.,LTD All Rights Reserved. ICP:琼ICP8565243号

Address:Hainan Haikou, Guomao Road, Beijing Building Tel:(86-898)66729565 36667880